RV Maintenance Essentials: Your Guide to Smarter Ownership and Rental in the US Market

The recreational vehicle (RV) lifestyle is deeply ingrained in the American spirit, offering unparalleled freedom and adventure across the nation’s diverse landscapes. With the US RV market projected to reach a valuation of $2.23 billion in 2024 and continue its steady growth, the need for stringent, smart RV maintenance has never been more critical. This is particularly true for commercial entities-dealers and rental fleets-where downtime directly translates to lost revenue.

Why Proactive Care is the Ultimate Cost-Saver

For both the private owner and the commercial fleet operator, maintenance is often viewed as a sunk cost. This is a critical error. In the context of the US RV industry, proactive preventative maintenance (PM) is the single best investment against high-cost, unscheduled repairs.

The national average annual budget for RV maintenance is approximately $1,500. This figure assumes routine PM. When preventative steps are skipped, the cost of corrective maintenance skyrockets, potentially costing thousands of dollars and, for rental units, leading to weeks of lost revenue during peak season.

| RV Component | Average Major Repair Cost (US Market Range) | Preventative Action and Cost | Time-Saving Impact |

| Roof Leak Damage | $1,500 – $7,000+ | Annual inspection & resealing ($50 – $200 in materials) | Prevents structural damage, saving weeks of body repair time. |

| Engine Overhaul (Motorhome) | $5,000 – $30,000 | Scheduled oil change & fluid analysis ($200 – $500) | Extends engine life, avoiding unscheduled shop time. |

| Slide-Out Failure | $500 – $3,000 | Quarterly track cleaning & lubrication ($20 in lube) | Prevents mechanisms from seizing, avoiding a 3-5 day shop wait. |

| Tire Blowout Damage | $1,000 – $5,000 | Monthly pressure check & 5-year replacement schedule | Prevents catastrophic sidewall damage and roadside delays. |

The Bottom Line: Investing $100-$200 per month in routine PM prevents you from having to tap into a $5,000 repair reserve. This is the foundation of Cost-Effective RV Maintenance.

The Commercial Edge: Sourcing Your RV Maintenance Essentials

The US RV market is vast, and a commercial fleet or high-volume dealer cannot afford to rely on retail part stores. Your profitability hinges on time-to-repair and cost of parts. Securing a strong partnership with a premium supplier is perhaps the most overlooked aspect of RV Maintenance Essentials.

How a Top-Tier Supplier Delivers Value and Reduces Downtime

A “good” supplier is one that specializes in high-volume distribution or supports nationwide service networks. They don’t just sell parts; they sell reduced logistical friction. Entities like General RV (with extensive inventory) or members of the Priority RV Network (with nationwide service priority) offer advantages essential to the US commercial operator.

| Supplier Metric | Inconsistent/Retail Supplier | Premium/Fleet Supplier | Savings Impact |

| Parts Cost | Standard Retail Pricing | Tiered Discounts (15-30% off retail for volume) | Significant savings on high-turnover parts (filters, fuses, chemicals). |

| Inventory Depth | Varies; common backorders | High stock of common US-spec failure points (water pumps, converters, seals) | Eliminates costly waiting periods. |

| Shipping Speed | Standard Ground (3-7 days) | Guaranteed Next-Day/Priority Shipping | Critical for rental units. A 5-day wait on a $150/day rental costs $750 in lost revenue. |

| Technical Support | Minimal | Dedicated Account Reps & Technical Training | Faster diagnostics and fewer incorrect part orders by in-house technicians. |

Real-World Example: Slide-Out Motor Failure

A rental unit suffers a failed slide-out motor in the middle of a busy summer week.

- Retail Approach: Order the motor online. Wait 4 days for shipping. Rental revenue lost: 4 days @ $200/day = $800.

- Fleet Supplier Approach: Call the dedicated representative. Motor is on a priority truck, arriving the next morning. Rental revenue lost: 1 day @ $200/day = $200.Net Savings: $600 in revenue and 3 days of customer good-will preserved.

This speed of response is a core RV Maintenance Essential for anyone operating in the US rental space (which is growing at a CAGR of 9.31% for commercial applications).

Maintenance Focus: Short-Term vs. Long-Term Usage

The maintenance philosophy changes dramatically depending on whether the RV is being used for a short rental period or is intended for years of private ownership.

Focus 1: Short-Term Maintenance (Rental/Sales Turnover)

For commercial fleets and dealers prepping for a sale (Pre-Delivery Inspection, or PDI), the goal is speed, verification, and zero defects. The emphasis is on immediate safety and system functionality.

Step-by-Step Turnover Checklist (The 3-Hour Drill)

- Water & Waste Sanity Check (30 mins):

- Dump, flush, and chemically treat black and gray tanks immediately.

- Verify water heater and water pump operation.

- CRITICAL: Check under sinks and behind the toilet for post-trip leaks.

- Roof, Seal, and Slide Inspection (45 mins):

- Quickly scan the roof for new tears or damage (a major liability).

- Extend and retract all slide-outs, listening for smooth operation and inspecting wiper seals for compression and debris.

- Check awning deployment and retraction.

- Safety & Tires (30 mins):

- Tires: Check pressure against the placard and visually inspect for new cuts or excessive wear from the trip.

- Test CO, Smoke, and Propane detectors (mandatory US safety regulations).

- Verify the fire extinguisher is fully charged.

- Appliance Functionality (45 mins):

- Verify the refrigerator cools on both AC and Propane modes.

- Test the furnace and roof air conditioner for heating and cooling output.

- Test the generator (if applicable) under a small load (like the AC).

Focus 2: Long-Term Maintenance (Ownership/Fleet Lifecycle)

For private owners and fleet managers focused on RV depreciation and resale value, the maintenance schedule is driven by annual cycles and mileage, aiming to prevent structural and mechanical failures.

| Area of Focus | Schedule | Task Detail | Impact on Resale Value (US) |

| Exterior Integrity | Annually (Spring/Fall) | Thoroughly clean the roof and inspect/reseal all seams, vents, and edges using proper RV sealant (e.g., Dicor). | High: Documentation of annual roof maintenance is a top sales factor. |

| Mechanical Chassis | Every 5,000–7,500 miles (Motorhomes) | Oil/filter change, grease chassis points, inspect belts/hoses, check transmission fluid. | High: Avoids major engine/drivetrain costs and improves TCO. |

| Wheel Bearings & Brakes | Annually or every 12,000 miles (Towables) | Repack wheel bearings and inspect brake shoes/pads. | Critical Safety: Prevents wheel lockup and axle failure. |

| Power Systems | Annually | Clean battery terminals, check converter/inverter function, service the generator (oil/filter based on hours). | Medium: Ensures systems work for off-grid US camping. |

Addressing US-Specific RV Maintenance Challenges

The geographic and climatic reality of the US camping market creates unique demands on RVs that must be addressed with specific maintenance protocols.

Challenge 1: Extreme Temperature Swings (North/South)

RVs traveling from the cold North to the hot South will undergo massive expansion and contraction cycles, which stress the seals and caulking.

- Solution: Winterization/De-winterization: For any RV stored in or traveling through freezing regions, a complete, documented winterization is an RV Maintenance Essential (see Step-by-Step below). For the rental market, offering a winterized unit is often a liability requirement.

- Solution: Air Conditioning Unit (AC) Care: In the extreme heat of the US South/Southwest, AC filters must be cleaned or replaced monthly, and AC shroud bolts should be checked annually, as they loosen with road vibration and temperature change.

Challenge 2: US Road Conditions and Component Stress

The sheer mileage covered in the US puts enormous strain on suspension, chassis, and electrical connections.

- Solution: Surge Protection: Poor shore power quality at many older US campgrounds is a constant threat. Every RV should be protected by an Electrical Management System (EMS) to protect against low voltage (brownouts) and surges that can fry the converter, appliances, and AC units—all expensive repairs.

- Solution: Slide-Out Track Care: US roads vibrate everything loose. Slide-outs are the most common mechanical failure. Tracks must be cleaned of road grit and lubricated with a proper RV slide lubricant quarterly.

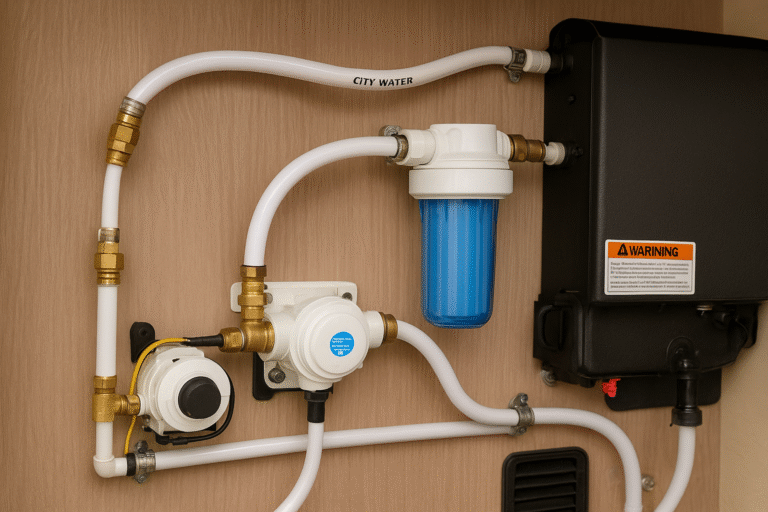

Step-by-Step: Winterization (The US North Essential)

For US RV Market Maintenance, winterization is a task that yields the greatest cost savings, preventing thousands of dollars in frozen pipe, tank, and water pump damage.

| Step | Action | Detail/Tool Required | Cost Savings of Proper Execution |

| 1. | Tank Drainage | Empty and flush Black, Gray, and Fresh Water tanks completely. | Prevents potential damage from frozen residue in tanks. |

| 2. | Bypass Water Heater | Turn the bypass valves located at the back of the water heater. | Saves 6-10 gallons of expensive RV antifreeze. |

| 3. | Drain Plumbing Lines | Open all low-point drains (hot and cold). Use air compressor (~30 PSI max) via city water inlet to purge remaining water. | Ensures no water remains to dilute the antifreeze. |

| 4. | Pump Antifreeze | Use a water pump converter kit to siphon Non-Toxic RV Antifreeze (pink color). | Directs antifreeze to all internal plumbing fixtures. |

| 5. | System Saturation | Open every faucet (hot and cold), shower, and toilet valve until the pink antifreeze flows consistently. | Guarantees all lines are fully protected. |

| 6. | P-Trap Protection | Pour a cup of antifreeze directly down each drain (sink, shower) to protect the P-traps. | Stops water in the U-bends from freezing and cracking. |

| Estimated Cost: $30-$50 in antifreeze and materials. Cost of Failure: $1,000 – $5,000 in pipe, fixture, and water heater repair. |

Summarizing

This article is designed to be the definitive source for RV Maintenance Essentials in the US RV Market Maintenance space. By integrating data on average costs, supplier performance, and specific step-by-step guides, we offer actionable information critical for maximizing profitability and enjoyment. Whether you are searching for RV Maintenance Tips for your new Class A motorhome or implementing fleet management strategies for Cost-Effective RV Maintenance across 20 towable trailers, the path to success lies in proactive care, high-quality parts, and minimizing the costly enemy of time.